Incorporated in 2003, we are a pipe stress analysis consulting company offering high level of expertise in Piping stress analysis using CAESAR II (Piping flexibility analysis) as per following codes:-

1) ASME B 31.3 & 31.1 :- Analysis of high temp lines as per ASME B31.3 / 31.1 for metallic piping for chemical plants, refineries and power plant.

2) IBR Code for Steam lines for Indian plants :- (For lines falling under Indian Boiler Regulation):-IBR Steam piping analysis as per IBR code for Indian projects, preparation of documentation for IBR submission and approval, like IBR piping analysis report / flexibility Analysis Report, IBR isometrics. Projects involves pipe stress analysis and support detailing of steam power plant lines like boiler piping, turbine lines and steam distribution network.

3) ISO 14692 :- Analysis of FRP piping as per ISO 14692. Largest project executed in FRP piping analysis, consisted 700 lines.

We work for

- New projects :- For new piping installation.

- Existing Plants :- For modifications in existing plants.

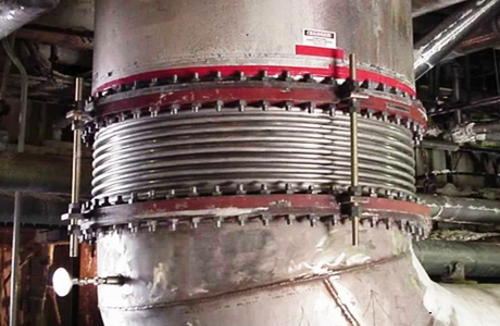

- Troubleshooting in existing plants :-Detection of causes of leakage, piping vibration, flange leakage, expansion joint failure, cracks in piping, pump misalignment, pump vibration, frequent pump seal failure, frequent pump bearing failure and other mechanical failures in piping and equipment.

- Training Services :- We provide training services in piping stress analysis to corporate.

We serve more than sixty clients worldwide, which include, world renowned EPC companies and some large fertilizer complexes. We are assigned an Import Export Code number from ministry of commerce of government of India.

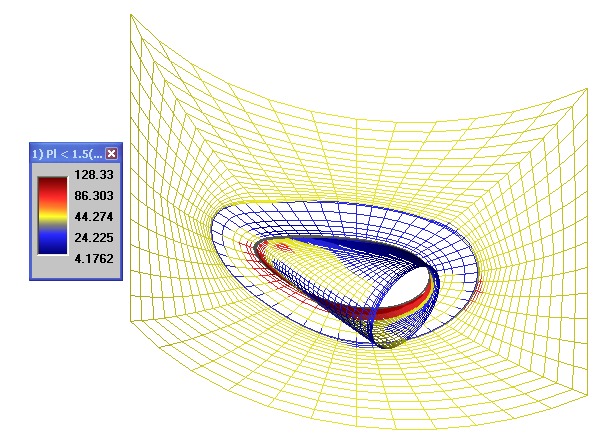

FEA Analysis

Analysis for attachments to pressure vessels using Finite Element Analysis..

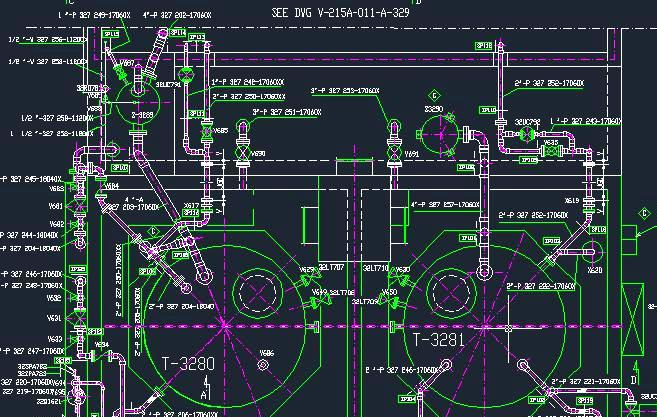

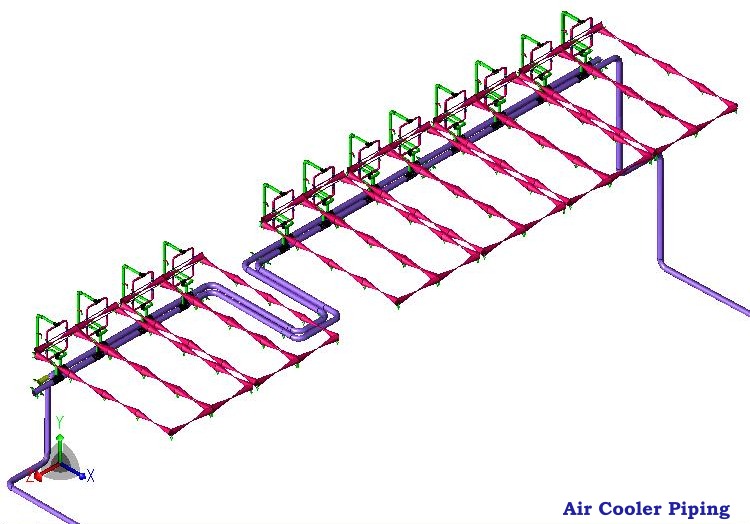

Flexibility Analysis

Pipe stress analysis (Piping Stress Analysis, Piping Flexibility Analysis) using CAESAR II

Troubleshooting

Piping Analysis to detect causes of various piping failures in existing plants

CAESAR II®

CAESAR II is widely accepted software in the consulting engineering industry by most engineering consultants and Clients. CAESAR II is used for piping stress analysis of metallic and FRP piping analysis, IBR piping analysis, flange leakage analysis, WRC107 analysis etc

.

Nozzle Pro™

NozzlePRO™ is a Finite Element Analysis software used for local load analysis of attachments to equipment and pipes like Nozzle to shell joint, nozzle to dish joints, nozzles on cones, nozzles on flat heads, platform cleats, piping cleats, trunnion connections etc

- For an old large petrochemical plant for some major critical process lines, a project to inspect old spring functioning and suggest replacement by performing analysis by field measurement of lines, preparing isometrics etc and issue spring specifications for ordering.

- Received an order for analysis of 100 critical process lines for a LPG Extraction plant

- Received order for analysis of 25 IBR steam lines from a specialty chemical manufacturer

-

Received a large order from a petrochemical company for analysis of large bore HP,MP and LP IBR steam lines from new boiler, steam turbine to all existing facilities and new upcoming plant.

- Received an order from a fertilizer company for analysis of Compressor/Expander lines for modifications and recommendations to mitigate various misalignments observed during commissioning.

- Received an order from a large sugar company for analysis of lines for a cogen power plant.

To be a prominent and well-known provider of competent and cost-effective engineering design services.